Experts in aluminum extrusion machining solutions

Extrusion machining solutions are Modig Machine Tool’s expertise. We are experts in developing, engineering, and producing high-performance manufacturing solutions for aluminum extrusion machining. Our machines are trusted by leading industries such as aerospace, automotive, and window and door manufacturers. Our machining solutions for extrusions are equipped with one or two spindles designed to boost your productivity. We would be delighted to review your business case and demonstrate the advantages of MODIG Technology.

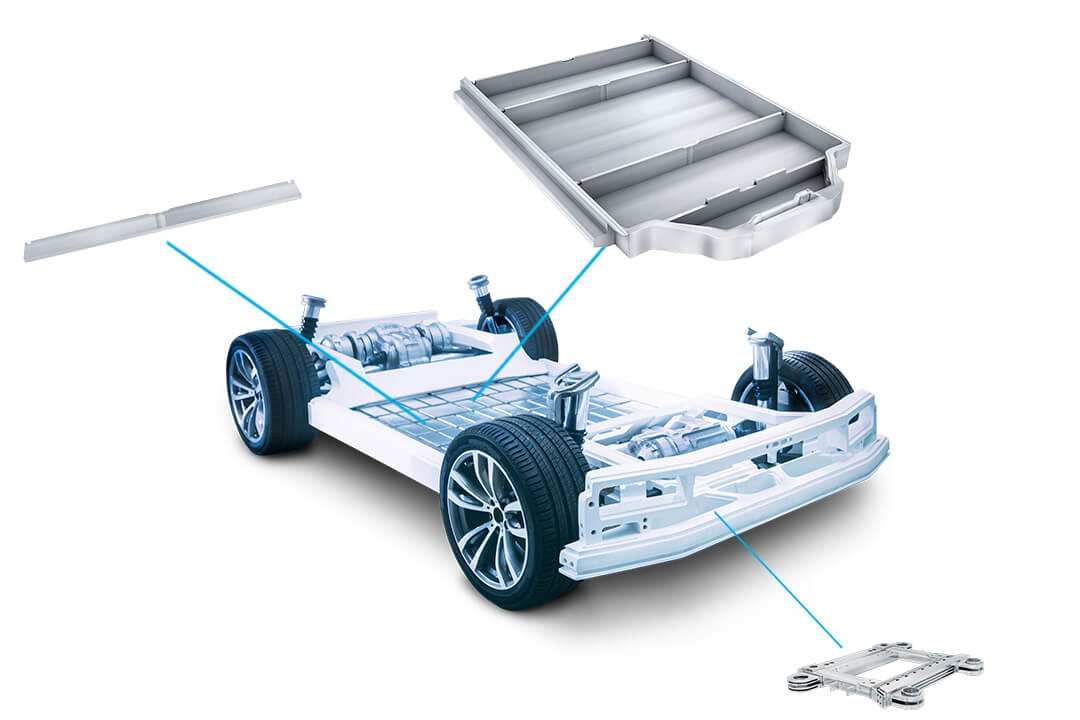

Automotive

Our CNC machining solutions for extrusions add value for automotive part manufacturers. We offer solutions for sills, front cradles, subframes, cross members, crash boxes, and battery trays.

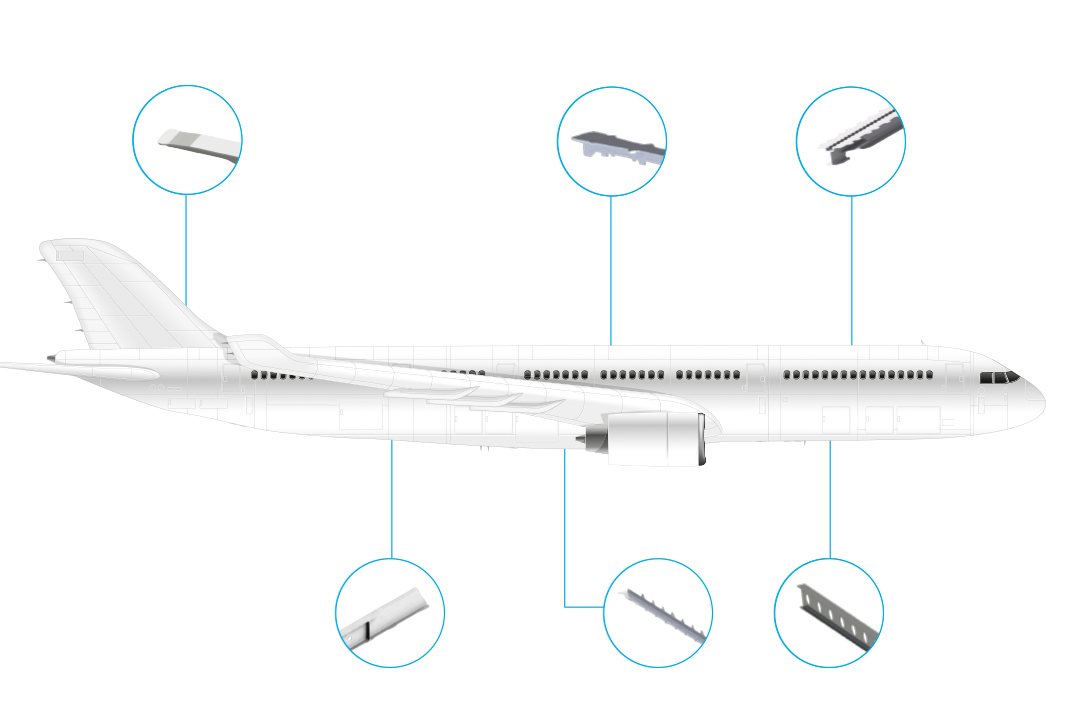

Aerospace

Find your CNC machining solution for aerospace extrusion parts, such as wing spars, wing stringers, seat rails, and floor beams. We have extensive experience in providing extrusion machining solutions.

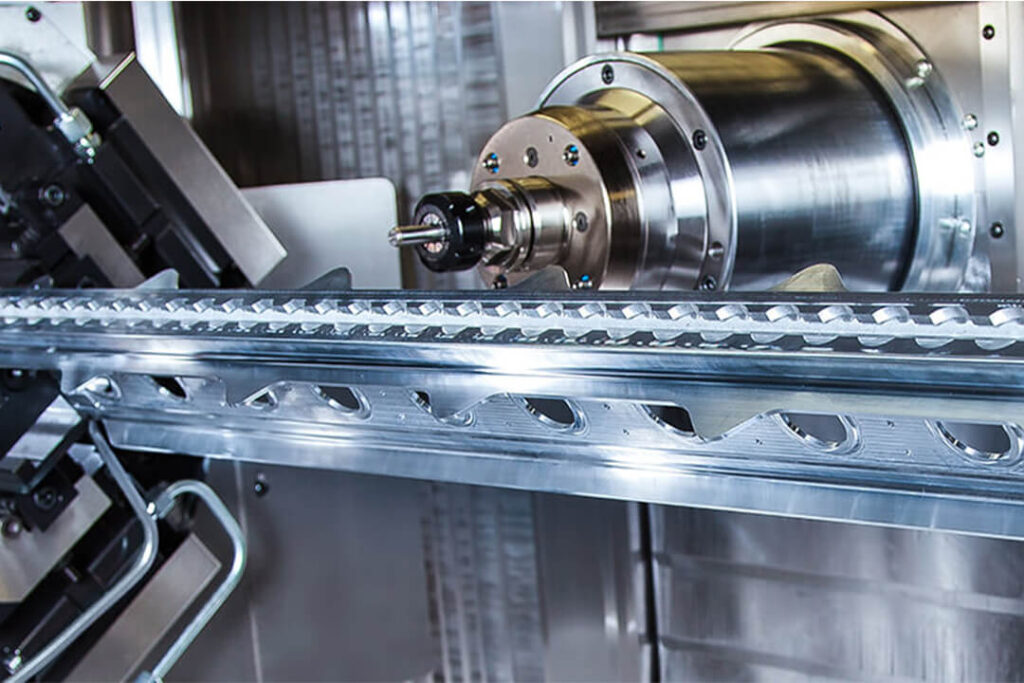

Witness our extrusion machining technology in action!

MODIG has stayed at the forefront of manufacturing solutions for extrusion part machining since the launch of the world’s first machine featuring a rotary table. We have gained valuable insights into the machining process through continuous improvement and customer feedback. Today, our horizontal machining centers for extrusion part machining can handle any extrusion shape in a single setup without any work holding required. Watch our videos to gain more insight into Modig technology for aluminum profile machining.

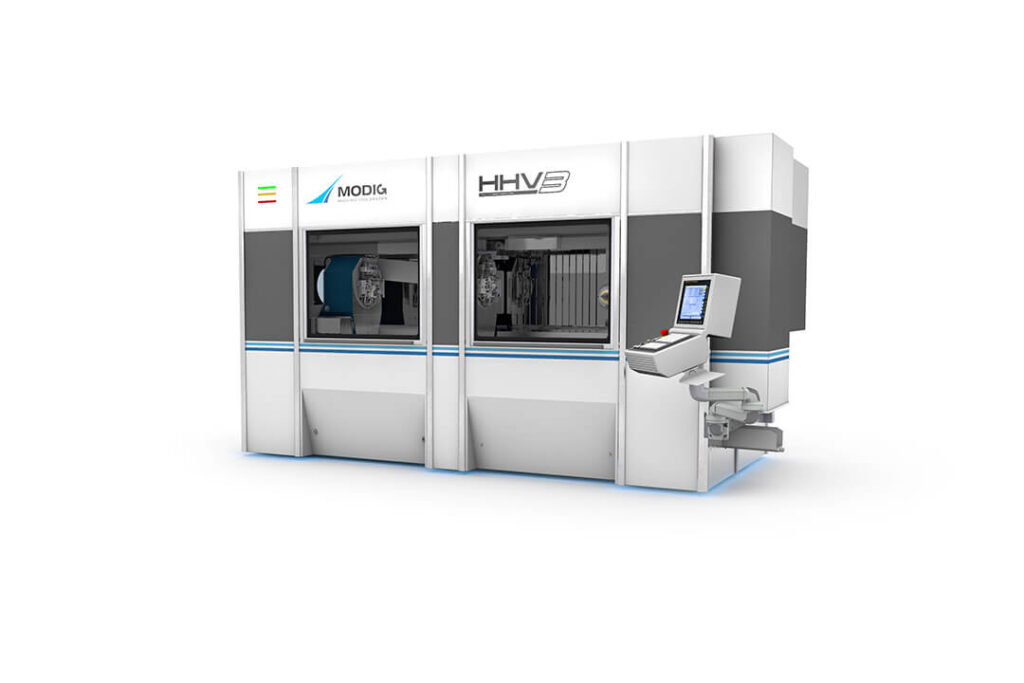

Extrusion Machining centers from MODIG

MODIG has a wealth of experience developing and constructing extrusion machining solutions for part and component manufacturing. We take pride in launching the world’s first rotary table extrusion processing machine in 1989. Since then, we have consistently pushed the boundaries of what is achievable in extrusion part machining with our technological expertise. As a result, today, we offer some of the fastest and most reliable machines for processing aluminum profiles. Our production solutions for machining aluminum profiles are up to 70 percent faster than competing five-axis standard machines while saving 20 percent more raw material.

Our solutions come equipped with two [HHV2] or three rotary tables [HHV3], one or two spindles [HHV DUO], and two or four spindles [Mill-Ex], allowing for the processing of straight bars and extrusions made of aluminum and composite materials.

What is an extrusion machining center?

The extrusion process

Extrusion is a metal-forming manufacturing method to create objects with specific cross-sectional profiles. To start the process, a pre-shaped die presses a heated, cylindrical aluminum bar called an ingot. The die works as a tool to shape the aluminum as it is pushed through the matrix, similar to squeezing toothpaste out of a tube.

When the profile leaves the tool, air or water cools it down. Then, the shapes are stretched while they are still ’soft.’ This way, stresses are released in the aluminum, and the profiles finally get the correct dimensions. The profiles are cut and get their final strength through hot or cold aging. The next step is finishing or surface treatment to enhance appearance and corrosion properties. After the surface treatment, you can use an CNC machining center to process the profile further and produce parts according to your specific requirements.

Extrusion machining center

A CNC machining center for machining extruded parts is a machine you use to cut and shape the extrusion into a finished part precisely. To achieve the shape you desire with pockets, holes, and other features, the extrusion machining center utilizes techniques such as sawing, deburring, drilling, turning, milling, and tapping. Its responsibility is to ensure the extrusion is cut and shaped perfectly.

In MODIG’s machine portfolio, you will find several machining centers for aluminum profile machining, HHV2, HHV3 and HHV DUO. Our machines are known for their speed and reliability in this type of machining. MODIG’s machines can significantly reduce production time and minimize waste during processing, making them a top choice on the market. Contact us to learn more about the MODIG solutions!

Industries using extrusion machining

Many industries widely use aluminum profile machining for its cost-effectiveness and time efficiency. The automotive industry has utilized extrusion solutions for many years, and manufacturers of electric vehicles require this type of machine to fabricate various parts and components, including battery trays, enclosures, and more. Similarly, the aerospace industry has also benefited from the advantages of extrusion.

Construction has increasingly favored aluminum extrusion due to its high strength-to-weight ratio and cost-effectiveness. Apart from commercial applications, several other industries extensively use the extrusion process. Learn more!

Articles worth reading

Read our articles about aluminum profile machining to gain deeper insights.

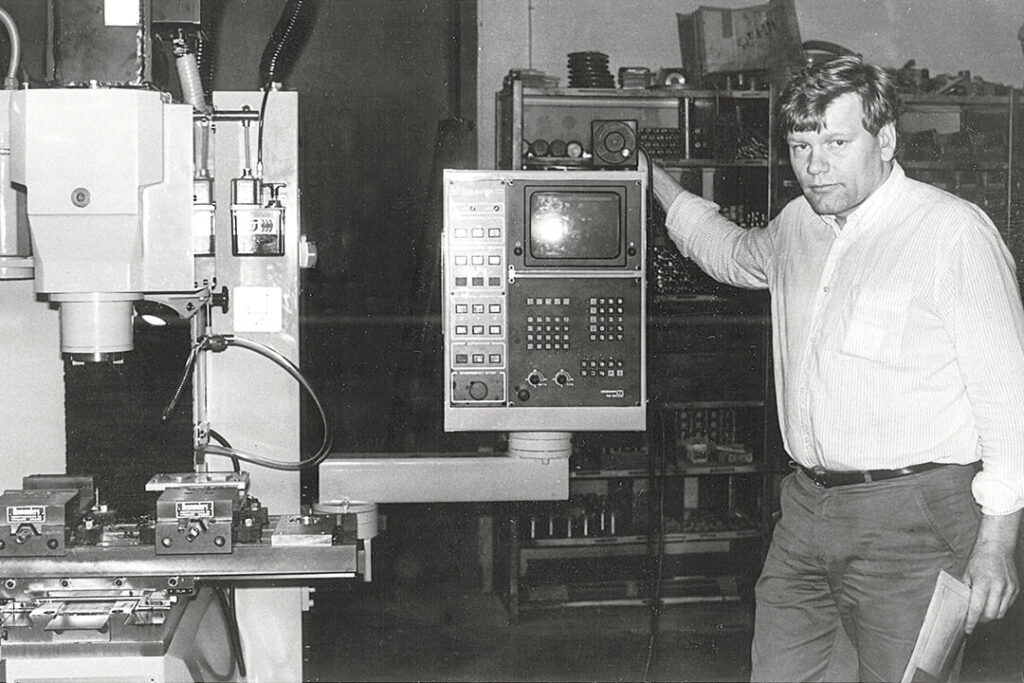

Modig Machine Tool, a pioneer in extrusion part machining, introduced the first machining center for aluminum extrusions with a rotary table over thirty years ago. Since then, the company has continued to advance its machines, providing an enhanced user experience.

Modig Machine Tool, SKF, and KTH collaborated to create the MD 7000, a high-speed and precise machine that utilized oversized ball bearings with ceramic balls, hardened steel rails and a computer control system to reduce vibrations

Extrusions play a significant role in shaping the world we live in, from buildings to objects around us, and this blog is all about extrusion machining.

Extrusion part machining: Frequently Asked Questions

Machining extrusions involves precisely cutting and shaping extruded materials—often aluminum or composites—into finished parts. This process utilizes sawing, deburring, drilling, turning, milling, and tapping techniques. The goal is to achieve complex shapes with pockets, holes, and other features in one seamless process, improving efficiency and reducing material waste.

A machining center for extrusion part machining, like those developed by Modig Machine Tool, handles the extrusion from raw material to finished parts. The material is loaded continuously into the machine and positioned automatically for machining without pre-cutting. Modig Machine Tools manufacturing solutions are designed to complete parts in a single setup, reducing cycle time and eliminating the need for multiple work-holding setups.

Machining of extruded parts is widely used in industries that require high precision and efficiency. The automotive and aerospace sectors are key adopters, using this technology to produce parts like battery trays, cross members, and seat tracks. Additionally, aluminum profile machining is common in construction, heavy equipment, and semiconductor manufacturing due to its cost advantages and high strength-to-weight ratio.